Gas Strut Application

ln their technical design, gas springs can be customized for special applications - on the basis of specifications and drawings. Match your application and requirements with us. 0ur application engineers will be glad to help you.

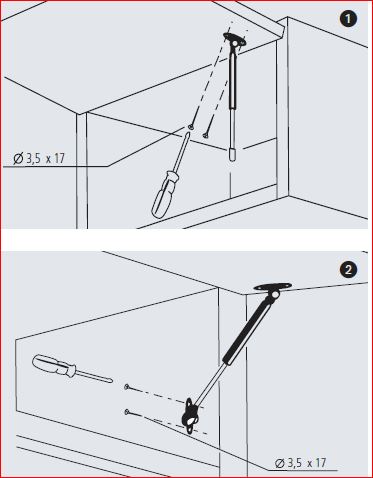

Proper Gas Strut Mounting Orientation

lf possible, install stabilus gas springs so that the piston rod points down in the inactive state - unless they were designed for non-orientation specific installation. This will ensure optimum lubrication of the guide and sealing system at all times.

No Jamming

For a long service life, your Stabilus gas springs must not jam or be subiected to bending or lateral forces. We offer suitable end fittings, such as angle joints. They will ensure non-jamming alignment.

Functional Safety

The functional safety of a Stabilus gas spring comes mainly from the smooth piston rod surface and the seals that keep the gas pressure on the inside. Do not subject gas springs to bending stresses. Gas springs that have been damaged in after-sales mechanical processing should not be used. Welding on the gas spring, as well as contamination or paint on the piston rod can cause device failure. Avoid modifications and manipulations, impacts, tensile stress, heating, painting and removal of the print. For safety's sake, do not install defective or improperly altered products.

Temperature Range of Gas Struts

Stabilus gas springs are designed by default for a temperature range of -30 degrees C to +80 degrees C.Of course, there are also gas springs for more extreme applications.

Life and Maintenance of you Stabilus gas Struts

Gas springs are maintenance-free! They do not require greasing or Iubrication. They are designed for their corresponding applications and should work flawlessly for many years.

Transportation and Storage

Store gas springs with the piston rod pointing down. Actuate the gas spring after 6 months of storage. Avoid damage: Do not transport gas springs as bulk material. Do not wrap in cling film or adhesive tape.

Proper Disposal of Gas Springs

When gas springs are no longer needed, they should be disposed of in an environmentally correct manner. For this purpose they should be controlled degased, the compressed nitrogen gas bled, and the oil drained. For more specific details, please refer to STAB specification 10009375. Please also consider our recycling instructions on our website www.Stabilus.com/service-spare-parts/recycling

GENERAL INFORMATION DISPOSAL OF STABILUS PRODUCTS

Highly pressurized products can be potentially dangerous. In order to eliminate these potential dangers the gas springs and dampers to be disposed must be immediately, i.e. without (temporary) storage, degased according to the instructions in this Stabilus-specification. During degasing the following general considerations as well as the special degasing instructions for the respective product types according to point 2.1 et seq must be observed. Disregard of these instructions can be hazardous.

In general the following applies:

- The pressure tube must be clamped between two V-blocks without being deformed and in such a way that dimension X is at least 25mm (see point 2.1 et seq). For STAB-O-MAT and STAB-O-MAT columns the entire pressure tube may be clamped.

- To degas, the pressure tube must be either slowly sawed open with a H A N D S A W or drilled open with a D R I L L B I T roughly 3mm in diameter at the specified location.

- Due to the high internal pressure in Stabilus Gas strut products, it is possible for metal shavings and/or oil to spray out from the sawing or drilling location. Therefore the necessary personal protection (eye and face protection, covering the sawing location) should be applied before sawing or drilling.

- For lockable Stabilus product the locking mechanism must be opened by actuating the release pin until the piston rod has been completely extended. After degasing actuate the release pin a second time to exhaust any remaining gas pressure in the product. Observe the necessary safety precautions according to Pt. 3.

- DORSTOP products must be completely extended before degasing

- The unpressurized product must be disposed of according to waste management laws. Gas springs and dampers are filled with oil. Waste oil must be disposed of according to waste management laws. Do not allow waste products into soil or natural bodies of water. - If disposal according to these regulations or the accurate identification of the product (according to Point 2.1 et seq) is not possible, it is recommended to consult with the supplying plant.